For lighting OEMs, we offer a variety of standard plaster frames.

But often our weekly conversations went like this:

Client: I need a plaster frame with a 100mm diameter hole.

Tripar: We have one with a 4” hole (101.6mm diameter.) Does that work?

Client: No, it has to be 100mm exactly.

Tripar: Okay, well in this case, we’ll blank these with no hole in our progressive die and then laser cut a 100mm hole. This being a 2-step process now is going to cost you more. Are you okay with that?

Client: Yes, that’s fine.

This got us questioning:

- What to do with the proliferation of luminaire dimensions requiring plaster frames with an increasing variety of hole sizes?

- Is there a way to offer clients more flexibility in plaster frame hole sizes; where they wouldn’t have to predict their sales/hole size requirements?

That’s when the idea struck to develop a plaster frame with adjustable hole sizes, like the aperture found in camera lenses. The problem is that camera lenses typically have upwards of 16 leaves and doing so for plaster frames would be very expensive.

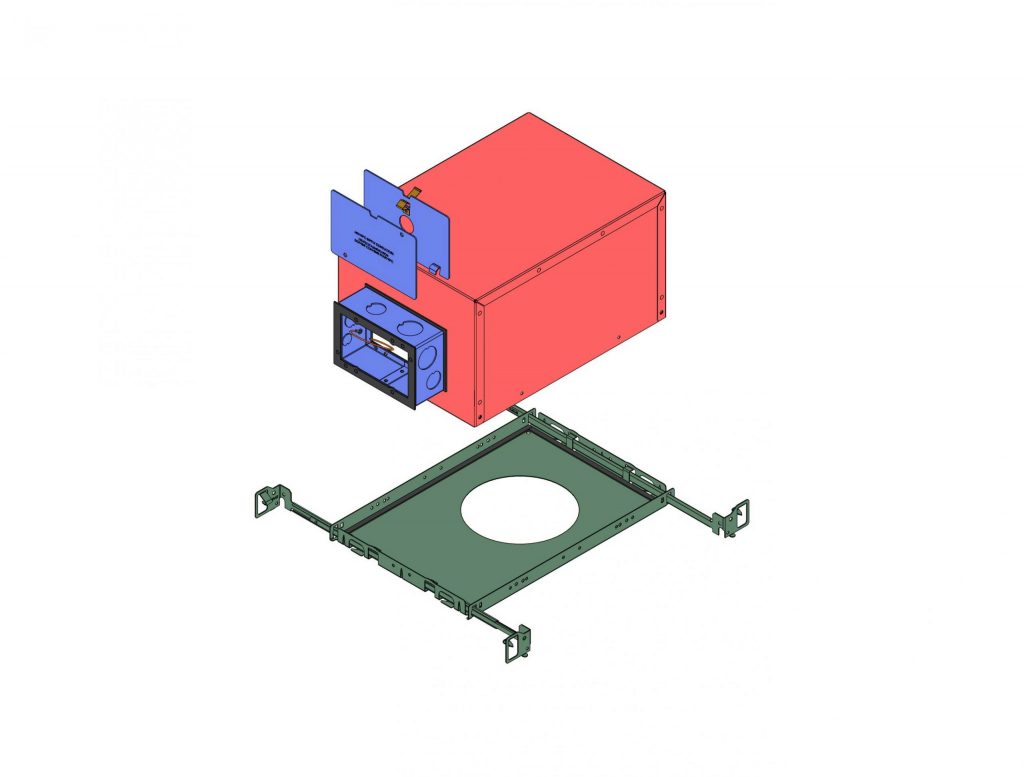

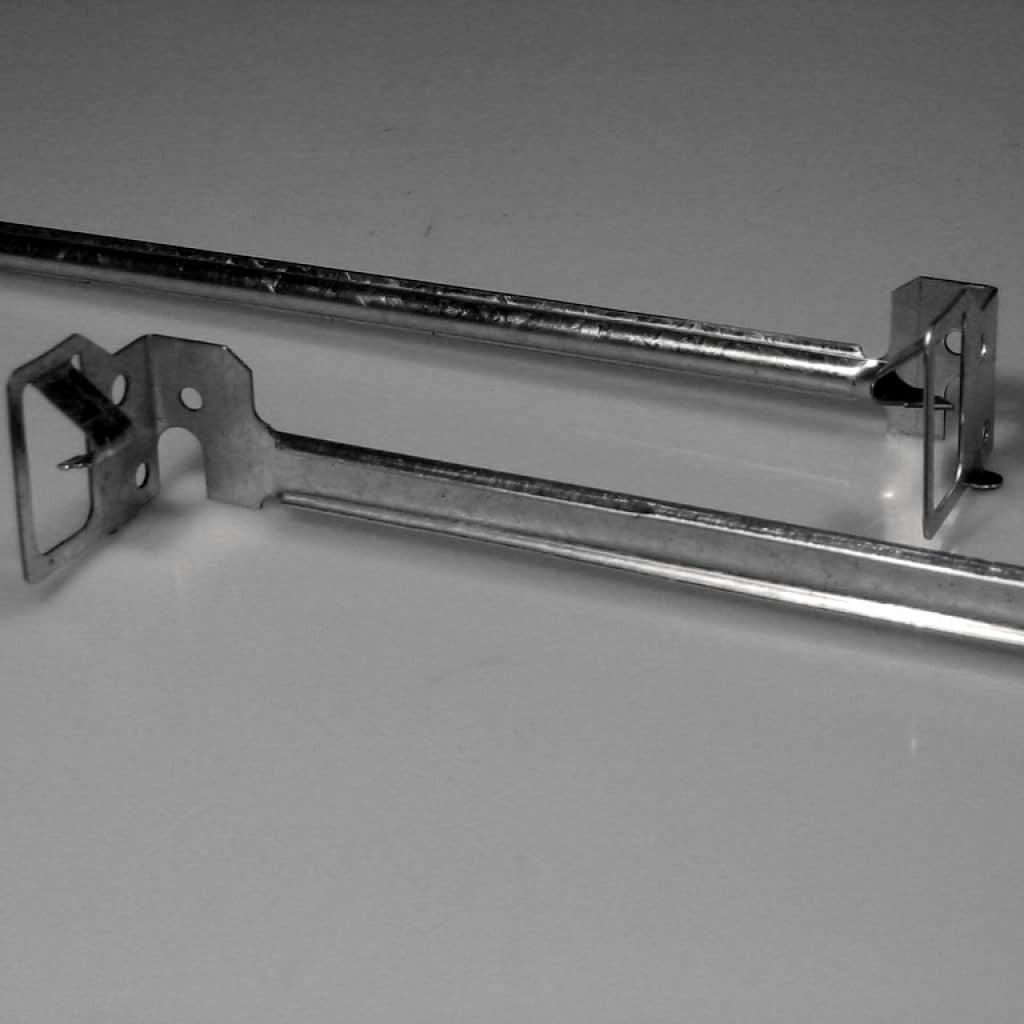

Turning to our engineers, we began an iterative process to redefine plaster frames by using a minimal number of movable stamped and fabricated sheet metal components. Slowly two concepts were flushed out, prototyped, eventually perfected, patented, and named The Shutters™.

The final design only has 6 leaves offering hole openings from 3” to 5-1/2”; all held together by a single fastener serving as a simple screw-lock to lock in the desired hole size. A few months later, we introduced the square Shutter™ upon client demand.

The Shutter™ round plaster frames

The Shutter™ square plaster frames

Why the Shutter™ plaster frames?

The Shutter™ provides cost-effective solutions for:

- Specialty OEMs requiring plaster frames of various hole sizes with low volumes.

- New lighting products where customers (or “OEMs”) don’t have a clear picture of which hole size will sell in higher volumes; the Shutter™ permits what would otherwise require a prediction of required hole sizes all in a single plaster frame.

- Large OEMs who buy fixed hole plaster frames in high volumes, upon seeing the Shutter™ order 500 to 2000 units. Why? Because should they run out of a plaster frame of a specific fixed hole size, rather than stopping production and being late on customer orders, they use the Shutter™ to keep orders moving along. They then reorder more to replenish their stock.

The Shutter™ is very popular and a hot selling item.