Introduction

Though I was still enjoying my time at Lee Valley, I still hoped to be back at Tripar one day. So back in early 2001 (when my Dad was 78 and still working full-time!), I approached him again (one of many conversations) about Tripar, its future, and me possibly being part of it someday.

Lloyd decides to approach Ben - From Lee Valley to Tripar

The differences this time were:

- That I told my Dad to do whatever he wants with the business, except the status quo, which was to do nothing in terms of the future. I reminded him of his age, and if something were to happen to him, the business would likely go down the drain.

- In September 2001, two of my girls would be switching schools; Alexine into high school, and Lauren into middle school. I explained to my Dad that I was not going to disrupt their lives after this, so if there was to be a way to get me into the business, it would have to be before the beginning of their new school year in September, otherwise, continue as is or sell the business.

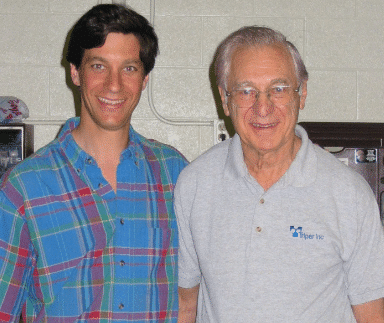

Lloyd & Ben - Two Generations of the Sevack Family

And so after many months of deliberations, my Dad and my uncle worked out an agreement, a leveraged buyout. This of course presented some risk, as Tripar, having previously been virtually debt-free, would have to take out a mortgage on the building to raise sufficient capital. The bank in turn said that their risk was dependent on me and my competence; should something happen to my Dad while the debt remained considerable. So, they made me meet with an Industrial Psychologist for a full day, at my expense, to assess my business, managerial, leadership, and other skills! To my surprise, I enjoyed the exercise. At the end, the Psychologist, asked me to describe myself, which I did…only to see almost my exact words in her final report, her describing me as if she had concluded this professional opinion after spending the entire day with me! The rest is history, I passed. My family moved to Montreal before the start of the new school year in September 2001. Back to my roots, working as Plant Manager alongside my Dad.

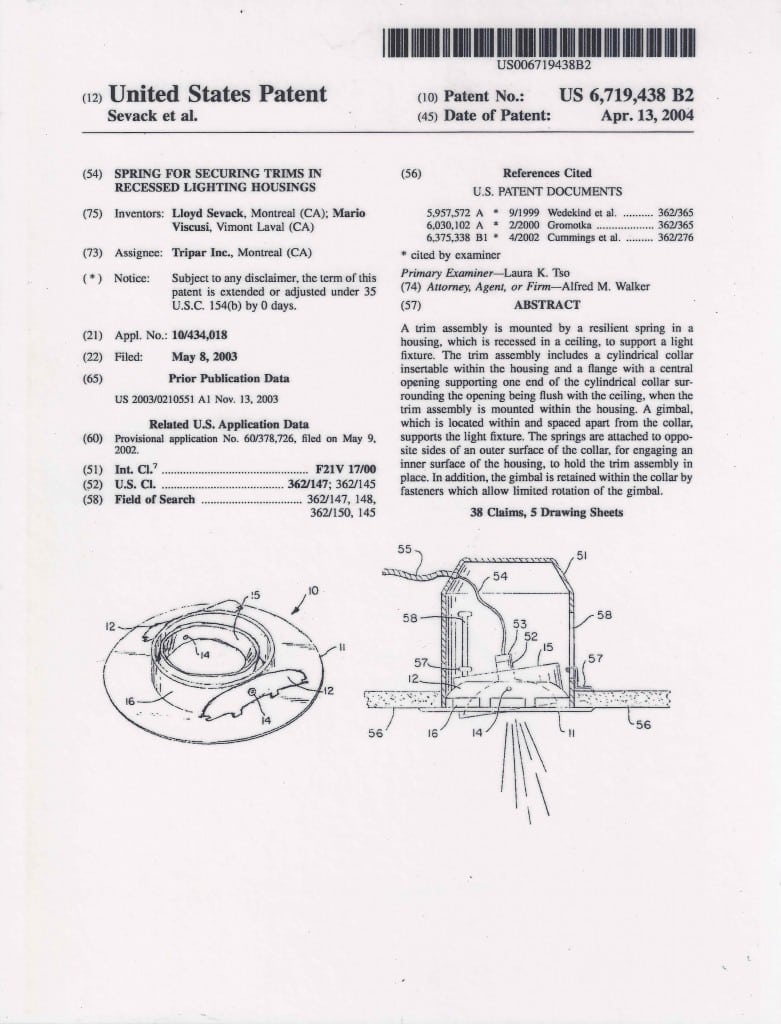

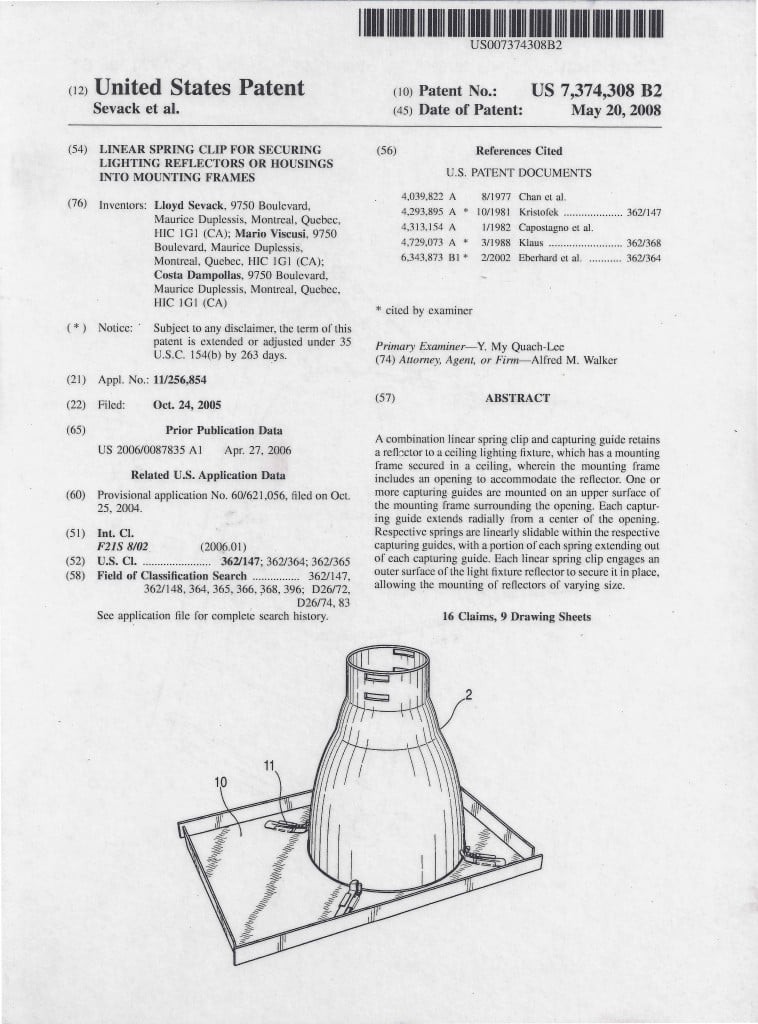

Capitalizing on my product development experience while at Lee Valley, Tripar I increased the pace of Tripar’s product development, and Tripar obtained its 3rd Patent in 2004; a spring for securing trims in recessed lighting housings. And also received its 4th Patent in 2008 for a Linear Spring Clip for securing lighting housings into mounting frames.

Tripar 3rd Patent - A spring for securing trims in recessed lighting housings

Tripar 4th patent - Linear Spring Clip

2003 also saw the forging of an agreement with Bill Brown Sales (BBS), to represent Tripar’s downlight (recessed) line in the US, with the obvious goal to increase sales there, a market 10x the size of that of Canada.

2004 was the year we threw out the old and almost non-participative suggestion program, replacing it with a new one. It was simple; identify a problem and come up with a potential solution. The employee with the best suggestion of the month gets a signed certificate AND 1-day paid vacation! Then the best suggestion of the year is selected from amongst the winners of the best suggestion of the month. The annual winner gets another signed certificate with a 1-week paid vacation! Since the program’s inception in 2014, we received over 350 suggestions, of which 180 have been adopted.

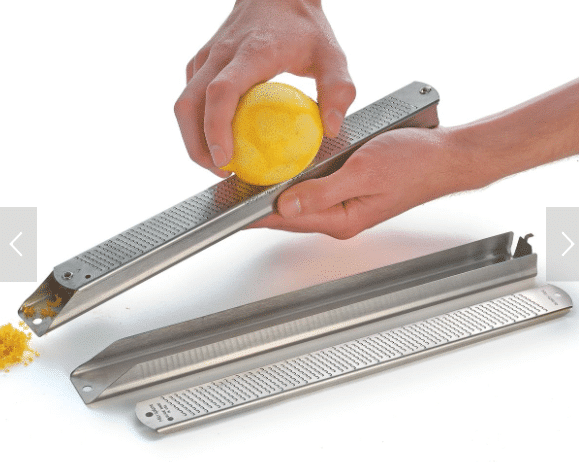

2002? Remember part of the 90s history, where Tripar began making parts for Lee Valley Tools and Veritas Tools? One of those items was a rasp holder to go with their Microplane rasp, used for culinary purposes, as a grater. Tripar obtained the contract to build a progressive die to make this stainless steel part.

During an intermediate part of the process, the entire permitter not only had to be deburred, but all edges slightly broken or rounded so this would be completely safe during hand use and washing. We contacted a few local deburring outfits, and tried several, with limited and disappointing results; the rasp holder would either come back filthy, or with either insufficient or overly aggressive deburring.

Having a 1” belt sander in my garage, I tried using this on a few parts, which seemed to work quite well. This led me to an idea, but first some related history.

Microplane Rasp made of Stainless Steel

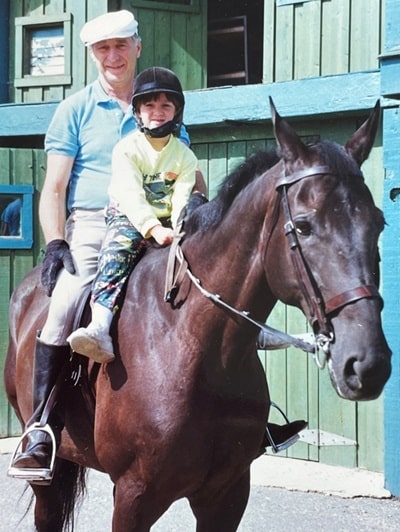

When my oldest daughter Alexine was around 4 or 5 years old, and obviously smitten with horses just like her grandfather, she asked what is perhaps not an uncommon childhood question; “Daddy, buy me a horse?”, to which I replied “Sure, as long as you can pay for the board”. With eyes lit up, she asked “Daddy, what’s board?” I explained this to her, but being only 4 or 5 at the time, I was not sure to what degree she understood. Over the years though, out came Alexine’s budgets and spreadsheets, trying to figure out if/when she could afford the board and upkeep. She also held odd jobs (such as newspaper routes back in the day), to help build her savings, but still not (yet) a steady enough income to pay for a horse’s upkeep.

Bringing home a box of 250 rasp holders (of what was to become a great many boxes brought to and from home), I offered the job, as piece work, to all of my three daughters, at 25 cents per piece; the same that the external deburring outfit was charging. Alexine jumped at the chance, thinking this could be her ticket to getting her horse. With some learning, dexterity, and even a few tears in the early stages, getting frustrated with the process, Alexine took this on, and became lightning quick at it! I recollect seeing her sitting in front of the 1” belt sander for hours at a time in the garage, with a dust mask, safety googles, and hearing protection, only to have music blaring over the top!

Well, the orders from Lee Vallery kept coming. She deburred tens of thousands of these, fattening her savings, whose sales appeared to be continuing. This, combined with her later part-time work in retail, Alexine reminded me of my early promise to buy her a horse. Having proved she could both save her money and continue earning, in the mid-2000s, I came through on my promise made when she was 4 or 5; and bought her first horse, Jazz. She kept him for quite a few years, during which she held her end of the bargain, never needing or asking me for a dime. At the age of 17, when she announced that she wanted to go to England to study horse dentistry! After some deliberation, we sent her off, and after 4 years of study, she obtained her B.Sc in Equine Dentistry. While there she met Andrew, who became her fiancé, and husband, and my new and capable son-in-law, who with his degree in Business Marketing, joined Tripar in the 2010s.

Alexine Sevack on Jazz

P.S. No, we did not ship Jazz off to England with her, but sold her, so I got my expense back…but not Alexine, as horses, though lovely, are also a money pit!

2005 was a momentous year for my Dad, and not in a good way. He fell off his horse at the age of 82. What was he doing riding a horse at 82? The same thing he had been doing most weekends for decades! During the fall, he broke his collarbone, but worse, that same arm got caught in the reins, and was pulled, detaching his right brachial plexus, the bundle of nerves that control that arm’s complete function. So, his right arm was paralyzed. Despite a nerve graft to try to regain some control, and numerous interventions to combat what is known as phantom pain, (a severe type of nerve pain), nothing helped other than a cocktail of pain medications, and only partially effective at that. Before this accident, my Dad was 82, going on 62. During the year following his accident, he probably aged ten years. I suppose I was lucky to have 4 years working by his side and learning from him.

Ben on his horse Teja & with Alexine

In 2006, at the 35th Anniversary of the CFIB (Canadian Federation of Independent Business), Tripar received an award for being a founding member of 36 Years; one more year than the official existence of the CFIB (remember the story in the 70s, of the origins of the CFIB and Tripar’s prior involvement?)! Here is the article: Tripar in the 70s!

CFIB Recognition

In 2007, Tripar received an Innovation Prize from the CNESST (Quebec Safety Board) for the development of its box lifter

Innovation Prize from CNSST

In 2008 Tripar won a prestigious “Estim” award. This award is presented annually by the Quebec Chamber of Commerce offering recognition to companies for exceptional success in their area of specialty. Tripar, was nominated in two different categories, Exporter, and Manufacturer, and received this award in the category of Best Manufacturer.

Prix Estim - Best Manufacturer

2009 marked Tripar’s 60th Anniversary

Toward the end of the decade, Tripar was receiving more than a few customer comments about how good we were at metal stamping, particularly if we had existing tooling, (or that which could be modified for minimal cost to suit customer specific requirements), with a “but”. The “but” was that if the customer’s quantities were insufficient to justify tooling, or the customer did not want to initially invest in tooling for a new product or component, we left them few options. They suggested that we get into CNC laser cutting or punching. To this, my answer was “oh, we’re metal stampers; what you’re looking for is a metal fabricator. That’s not us”. To this, they consistently replied “..but we like working with you”!

Unrelated at the time, was my visiting a certain customer in Montreal at their new plant in early 2009, having moved from an old dingy facility located in Verdun. Upon leaving their new premises, I distinctly remember thinking how nice I thought their new spacious and modern facilities were, and that I hoped they had sufficient revenue to cover it. Fast forward about one year; sadly, they did not, and hired an auctioneer to liquidate their assets. One of these was an Amada CNC laser, for which we were the successful bidder. And so, we entered the world of metal fabrication with our first laser, which would prove to be the first of many more pieces of CNC metal fabrication machines.