Trusted Experts since 1949

Sheet metal fabrication for OEMs

Whether you need 100 to millions of units annually. Designed and built to OEM standards.

- Full turnkey solutions

- Lead times from 3 business days

- Small to medium size components

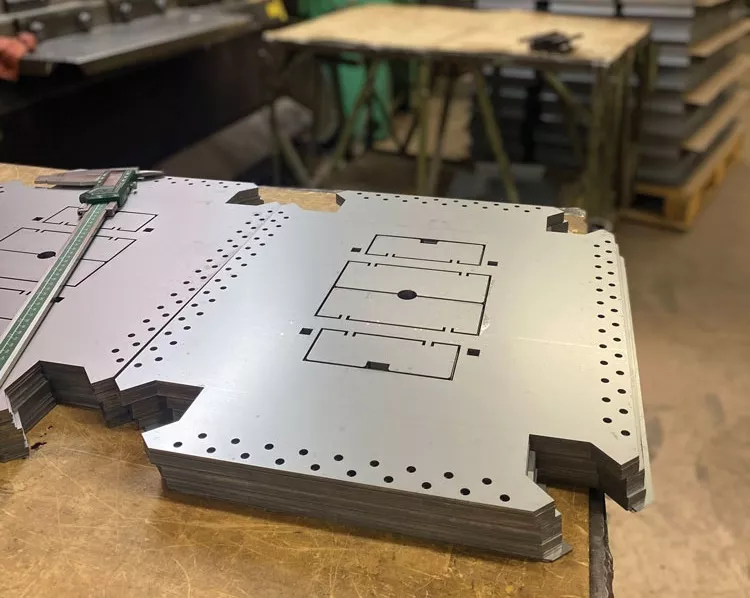

Metal Stamping

With 100+ presses, 1600+ open-tooled dies and expert in-house toolroom, Tripar’s capabilities include progressive stamping, blanking, punching, bending, engraving, marking, embossing, rolling, drawing and deep drawing. For high volumes and the lowest possible unit cost.

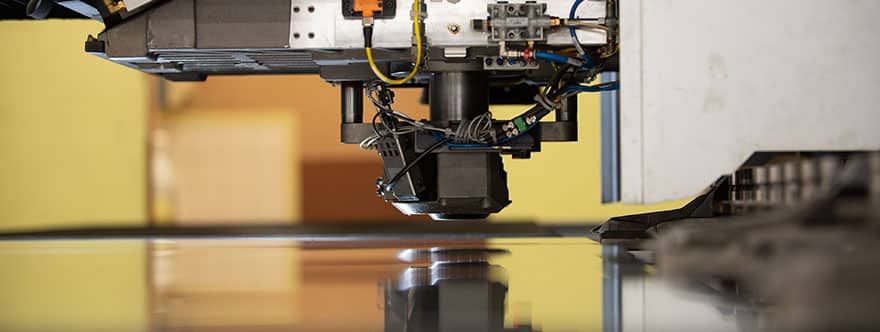

CNC Fabrication

With Tripar’s vast CNC capabilities and experience, we manufacture a wide range of sheet metal components through laser cutting, punching, bending, forming, spot welding, shearing, riveting, clinch joining and assemblies too. For low volumes and fastest lead times.

Serving 350+ OEM clients in the US, Canada, Europe

Recessed Lighting

Full line of stocked items: Plaster frames, I.C. Boxes, Junction boxes, Brackets, Hanger bars, canopies for UL1598.

HVAC

Experience manufacturing diffusers, grills, faceplates, louvers, housings, brackets, hinges, nameplates.

Warehouse Racking

Metal components includes shims, brackets and supports for new and existing warehouses.

Appliances/Furniture

Range of sheet metal components for central vacuums, extractor fans and storage cases

Aerospace

Many years producing engraving plates, shielding cans and washers

Engineering & Design Services

We offer design and engineering services for your sheet metal components; Design for Manufacturability (DFM), 3D modelling, technical drawings, optimizations, and prototyping.

Knowledgeable Team

Tripar is a successful family business with 75+ years. We proudly manufacturing everything under one roof with our incredibly talented and knowledgeable team.

The Tripar Advantage

A true scalable production

Tripar offers hybrid manufacturing; CNC fabrication, metal stamping, or a combination of both processes to reduce unit costs. Fewer than 5% of metal fabricators offer this. Unlike some suppliers, we are not tied to a single fabrication method. Based on the complexity and annual volumes of your parts, we will seamlessly migrate you from CNC fabrication, to hybrid manufacturing (savings of 30% and more), to metal stamping (savings of 200-300%.) No need to find new suppliers or worry if you're overpaying as quantities grow over time. We take care of it all for you.

We work with you at every stage of your manufacturing lifecycle; allowing you to optimize and scale your production. From design, engineering, die design & build, prototyping, fabrication, QA&QC, painting, assembly, packaging, and shipping - we do it all.

Want a free review & optimization of your parts?

Latest Articles

10 Tips to Optimize Your Sheet Metal Designs [DFM Part 1]

Poor designs are costly. In this OEM guide, we cover the dos and don’ts of optimizing your sheet metal components.

Tripar in the 2000s: Two Generations Joining Forces

The journey continues! In this special 75th edition, Lloyd talks about joining Tripar as Vice President; Tripar continuous growth & Tripar’s patents: third and fourth – all in the 2000s.

In The Media

Canadian Manufacturing

Home vent manufacturer scaling up and growing through partnership

Fabricating & Welding

A great story of Tripar’s hybrid manufacturing approach when quantities scale

Canadian Manufacturing

Two Canadian companies Aria Vent and Tripar Inc. form a collaborative relationship

Axya

Tripar Inc: Strength and Savings Through Domestic Production